SMD Rework Solution

We are specialist for SMD Rework such as 0402 chip, CSP,BGA and QFP etc.

RTTS555 Reflow Checker:

Home(Products) > RTTS555 Reflow Checker Details

RTTS555 is used with the windws PC.

The software can be analyzed of the data.

As for more details, please refer to the document "RTTS Operation Manual".

RTTS555 Wire-Less Reflow Checker

RTTS555 is used with the windws PC.

(with RS232C interface, and or USB2.0 by special cable)

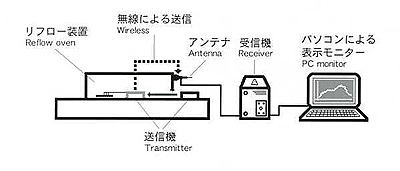

It is wire less real time data checker system.

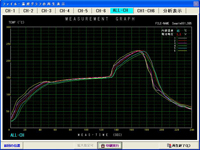

It has 6 colors of 6 channels data check.

The software can be analyzed of the data.

(a peak data and a time interval data for each channeles)

The data can be conversion to CSV format. (for Windows Excel)

The yes-no decision of the profile is possible for every channel.

As for more details, please refer to the document "RTTS Operation Manual".

Outline of Operation

|

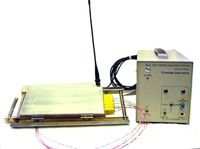

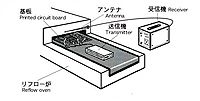

RTTS555 wire less reflow checker is for temperature profile measuring when reflow process. The sensor is used of the CA K type thermocouple, and it has six input terminals. The checker is used with widows PC, they should be connected by RS232C and or USB2.0 cable. The data can be printed out with the form specified to the A4 size paper. Of course, the data can be color specification.

|

RTTS555 Wire-less Profile Checker |

Analysing

The software which can do analysis of a time interval and a peak data is attached. The time interval is possible for every channel, If the set up temperature data is inputed. Then, each time data is obtained. Of course, it is also a peak temperature data. Those data is printed out, with the graph data. The maximum Y data is 300 C degrees and also X data is selectable from 2,4,6,7,8,10 min. It is because, RTTS555 is only for reflow process.The sensor

|

The attached sensor is 0.2mm Diameters x 50c m CA K type. It is connected with the transmitter, the data will be sending to the receiver with real time by wire less. In the case, The distance of data which can be transmitted is about 20m.

|

wire-less data sending system |

How to use the sensor

The sensor must be completely contacted to the board or the package. The graph will become zigzag, if the sensor not completed contacted to the subject. In that case, it has to adhesion to the subject. Since, the all most all mistake of temperature measuring will be a mistake by sensor trouble. Exactly temperature measurement is indispensable to exactly reworking.Automatic profile Check

Success or failure of the profile can be check for every channel with real time. The range of a judgment is set up beforehand, it is a dialogue on the screen, it is easy.Specifications

The specification are subject to change without notice. |

Standard Accessory:1. Transmitter x 1 2. Receiver x 1 3. AC power cable x 1 4 CA(K) sensor 0.2Dmm x 50cmx 6 5, High Temperature Tape x 1 6. Software FD x 1 7.RS232C cable x 1 8.Charger cable x 1 |

M.S.Engineering Co.,Ltd.

1-38-15, Okusawa, Setagaya-Ku, Tokyo, 158-0083 Japan. Phone: +81-3-4283-3951 Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

1-38-15, Okusawa, Setagaya-Ku, Tokyo, 158-0083 Japan. Phone: +81-3-4283-3951 Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

PDF for Printing

PDF for Printing