SMD Rework Solution

We are specialist for SMD Rework such as 0402 chip, CSP,BGA and QFP etc.

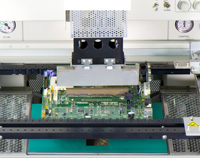

ND3000WP:

ND3000WP Rework Center

ND3000WP

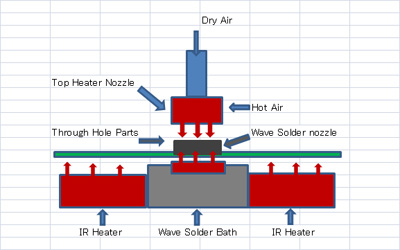

The solder bath is a jet flow system and a top heater by hot air is operated at the same time. Furthermore, in the wide bottom heater system by IR will be effective for the rework of the large size board and the prevent of the warped by the heating.

ND3000WP is the rework system to the through- hole board. It is best system for large-size connector etc.

Reworking is by jet flow soldering and combined of the hot-air and IR heating.

The nozzle for reworking can be change, Then all most all THD rework will be possible.

Lead free soldering is possible by the 3 zones heating with the pre-heating, jet cleaning and soldering. heating.

The touch panel controller with PID control system will be possible to easy and safety operation.

The optimal data can be save in the system, and it can reappear anytime.

Operation

ND3000WP is a reworking system for through hole type board. The machine has the solder bath, and it can be put in of the 50Kg solder. The top heater is by hot air system which it is in used in our SMD rework system. The supporting heater from the top, by the hot air heating system is made possible to rework of the parts with big heat capacity, such as connnector. In the case of reworking to the large size board and or the multi-layered board, the additional wide bottom heater by optional IR system will be very effective. It will contribute to good quality-reworking greatly.

Operation Data setting

Touched Panel Screen

ND3000WP has the touched panel control system. All most all of the operation and condition setting are possible on the touched screen.

Data setting Screen

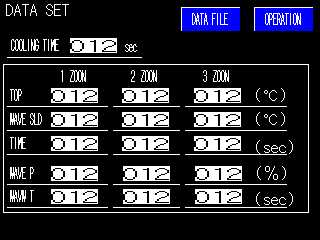

The heating process of ND3000WP has three zones.

The 1st zone is for pre-heating, the nozzle of the top and bottom, and also the board will be pre-heated for precise soldering.

The 2nd zone is for solder cleaning of wave-jet solder. It is idle operation of the solder jet. And it will be remove of the garbage and the oxidation film etc, from the jet solder.

The 3rd zone is for soldering. the wave jet solder is operated by the set temperature and time.

The size of the jet wave of solder is adjusted at every each zone.

Touched Panel Screen

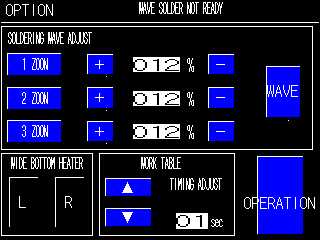

The condition of wave jet for soldering can be adjusted at the screen.

Furthermore, It can change of timing that the wave jet operation and the work table go up and down. It may become more better of the soldering condition.

Data File

Data File Screen

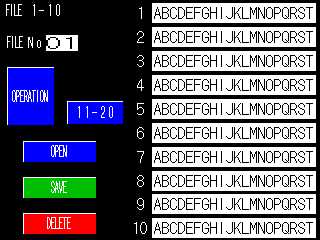

The completed setting data can be saving, on the screen. they are maxumum 50 files by 10 files each on the screen. It is possible anytime in reading, and or editing.

Target Plate

Lighting Target

The position of the reworking parts can be check by the target mark. It is the lighting mark of a cross. The positioning of the nozzle is possible easily by the mark.

Nozlle Change

![]()

Jet wave nozzle-----------Hot air nozzle

The nozzles should change to each size of the parts. It should have the range in which the range of soldering area of the parts. and it is better not too much.

Nozzle

Nozzles

The nozzles are made by request of the customer needs.They are designed to the size of the parts.

Specifications

| Item | Specification | |

| Solder Bath | 50 Kg max | |

| Board Size | 50 x 50 ---400 x 500mm max | |

| Board Thickness | 3.5mm /3Kg Max | |

| Unnder the Board | 25mm Max | |

| Work Table | Vertical Range 0--30mm Max | |

| Table Height Adjust | 30mm max | |

| Table Adjust Timing | 1st Zone | Pre-Heating 000---999 sec |

| 2nd Zone | Solder Clening 000---999 sec | |

| 3rd Zone | Soldering 000---999 sec | |

| Table operation Timing | 0---10 sec | |

| Data File | 50 max | |

| Top Heater | 1080VA Hot Air | |

| Wide Bottom Heater(option) | 1000VA x 2 IR (Option) | |

| Solder Bath | 1500VA x 2 cartridge | |

| Controller | PID Touched Panel Controller | |

| Nozzle | 90 x 100mm Max | |

| Power | 200--240V 4.5KVA | |

| Dimension | 660W x 730D x 750Hmm 130Kg approx. | |

| Air | 0.5Mpa Dry | |

The specification are subject to change without notice.

1-38-15, Okusawa, Setagaya-Ku, Tokyo, 158-0083 Japan. Phone: +81-3-4283-3951 Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

PDF for Printing

PDF for Printing