SMD Rework Solution

We are specialist for SMD Rework such as 0402 chip, CSP,BGA and QFP etc.

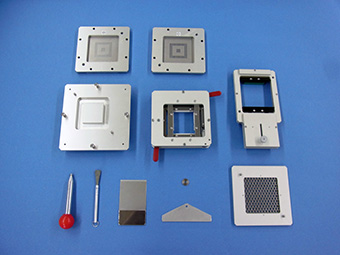

RBC-1 Re-balling Tool:

Home(Products) > RBC-1 Re-Balling Jig Details

The Land of the package should be cleaning first by solder cleaner, such as solder wick, etc.

Change the mask holder to the re-balling mask.

Probably, with an attached movement tool, BGA which ball mounting completed is easily movable to the heating process.

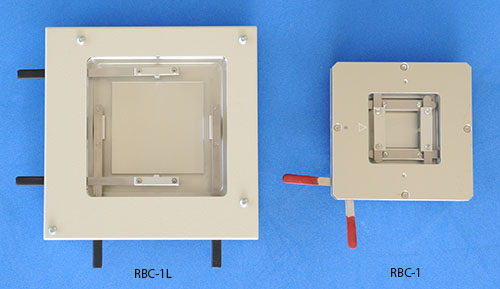

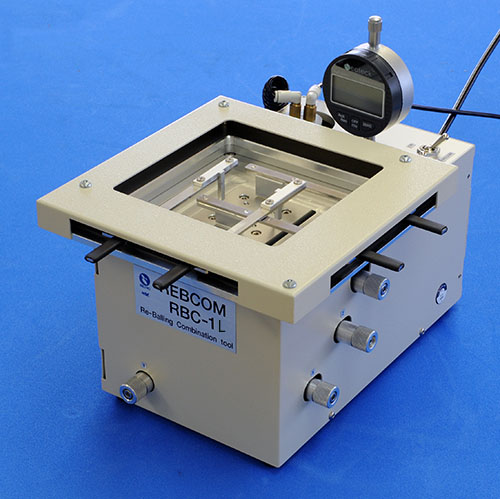

RBC-1 Re-Balling & Printing Tool (for almost all BGA)

DEMO MOVIE for Standard Model

DEMO MOVIE for Micro BGA

Re-Balling & Printing of almost all BGA is possible.

Positioning of BGA is very easy and exact. even rectanble BGA.

Since RB-1 is almighty, it become reduction of the cost.

Since RBC-1 is easy to operate, an expert is unnecessary.

Outline

|

|

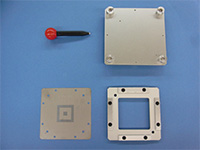

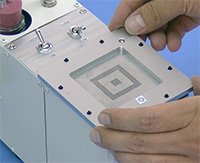

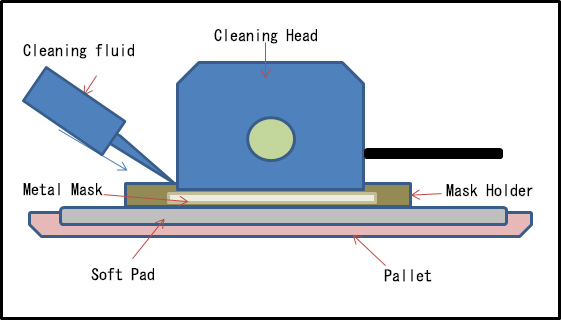

Re-Balling process-1: (Solder Printing)

|

Metal Mask Holder |

The Land of the package should be cleaning first by solder cleaner, such as solder wick, etc.

The package is able to set to RBC-1 by the auto centering unit, easily and exactly.

The metal mask for printing is setup to the mask holder has the guide pins, it completed by one-touch.

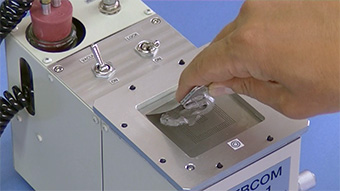

Solder paste is added and printing it by the squeegee.

After printing, the printing mask unit is removed.

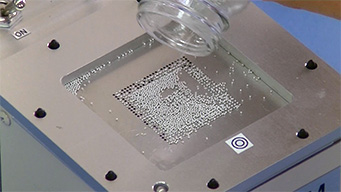

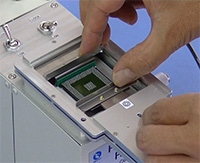

Re-Balling Process-2: ( Solder Ball added )

|

Re-balling Mask Holder |

Change the mask holder to the re-balling mask.

The re-balling mask holder is setting up instead of the printing mask unit.

Since exchange of each holder has guide pins, it completed by one touch.

Solder ball is poured in, Then remove the re-balling mask holder.

The excessive solder ball which suck up is send to the attached bottle.

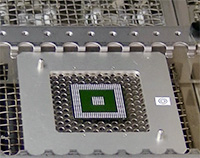

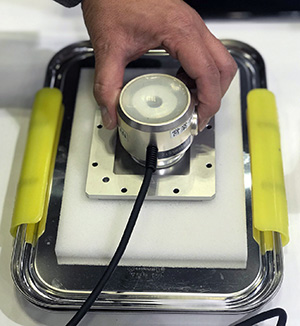

Re-Balling Process-3: (Solder ball heating )

The completed replaced ball on the BGA must be heating by the rework system. It is for fixed ball to the package. In that case. the heating temperature will be completion, if a solder ball adheres to the package. It will be lower to the soldering profile.

|

Movement Tool

Movement Tool |

After re-balling

Probably, with an attached movement tool, BGA which ball mounting completed is easily movable to the heating process.

RBC-1 Printing Operation.

|

|

RBC-1L responds to large-sized BGA up to 100x100 mm.

|

|

POP Adapter RBC-1A (Option)

Printing & Re-balling by PBC-1 is possible to the POP type BGA. In that case, it is required of the RBC-1A optional accessories.

|

|

Micro BGA Adapter RBC-1B (Option)

PRBC-1B adapter is used when the diameter of BGA is 0.3mm or less. The adputer is fixed to the printing mask and the drift by heating after positioning is prevented.

|

|

Special Accessories:

|

|

|

RBC-1 Maine Specifications: (RBC-100)

| Item | Description |

| Compornents | CSP/BGA/LGA/LLP/POP/QFN/etc |

| Package Size | 3.0 x 3.0 mm ~ 50.0 x 50.0 mm (□3x3~□100x100mm) |

| Balll Size | 0.1 ~ 0.76 D mm |

| Ball Pitch | 0.3 ~ 1.27 mm |

| Table Adjust | X / Y / Z : 0.01 minimum |

| Rottion Adjust | Up to 3.0 Degres |

| Air Supply | 0.15 ~ 0.8 Mpa (by 6D mm Tube) |

| Accessories | Mask-Holder for Print & Re-ball / Centering T |

| Carrier / Heating Tool / Squeegee / Ball H | |

| Optional Acc | RBC-1A(for POP)/-1B(for Micro ball)Adapter |

| Weight | 3.0Kg approx, (3.5Kg approx) |

Dimension |

130W x 250D x 165H mm approx.(160Wx280Dx230Hmm) |

M.S.Engineering Co.,Ltd.

1-38-15 Okusawa Setagaya-Ku Tokyo 158-0083 Japan.. Phone: +81-3-4283-3951 / Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

1-38-15 Okusawa Setagaya-Ku Tokyo 158-0083 Japan.. Phone: +81-3-4283-3951 / Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

PDF for Printing

PDF for Printing