SMD Rework Solution

We are specialist for SMD Rework such as 0402 chip, CSP,BGA and QFP etc.

ND5100:

Home(Products) > ND5300 Details

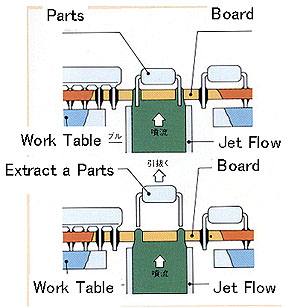

The solder bath is a jet flow system, and jet flow time is automatically operated by the controller which it was set up in advance. The reworked parts should be pull up by hand if process was completed.

ND5300 is a reworking system for through hole type board. The machine has the solder bath, and it can be put in of the 25Kg solder. When reworking, ND5300 is required the nozzle of the size suitable for the reworking parts.

Remove and soldering of the parts are same controlled operation on the machine. And operation of the machine is by foot switch. When reworking the parts of under the board, it is possible by lowering the work table.

The position of the reworking parts can be check by the target mark. It is the lighting mark of a cross. The positioning of the nozzle is possible easily by the mark.

ND5300 Rework Center

The solder bath is a jet flow system, and jet flow time is automatically operated by the controller which it was set up in advance. The reworked parts should be pull up by hand if process was completed.

ND5300 is the rework system for through- hole board.

Reworking is by jet flow soldering

The nozzle for reworking can be change, therefore, it can be reworking of the all most all parts.

Lead free soldering is possible.

It is a best seller machine with the actual result for 20years or more.

Operation

ND5300 is a reworking system for through hole type board. The machine has the solder bath, and it can be put in of the 25Kg solder. When reworking, ND5300 is required the nozzle of the size suitable for the reworking parts.

Controller

Remove and soldering of the parts are same controlled operation on the machine. And operation of the machine is by foot switch. When reworking the parts of under the board, it is possible by lowering the work table.

Target Mark

Lighting Target

The position of the reworking parts can be check by the target mark. It is the lighting mark of a cross. The positioning of the nozzle is possible easily by the mark.

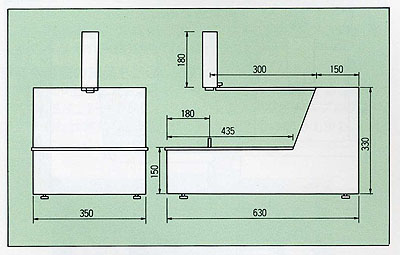

Dimension

Specifications

| Item | Specification |

| Solder Bath | 25 Kg max |

| Temperature Range | 200---350 C degrees max |

| Controller Accuracy | ±1C degree |

| Nozzle Size | up-to 50x80mm |

| Jet Flow | Variable Screw |

| Work Table | 350x 435mm |

| Table Height Adjust | 20mm max |

| Table Mat | Heat Resisted and Conductivity |

| Target Marking | Bright mark |

| Heater | High-density cartridge heater |

| Power | 100V 1.25KVA |

| Dimension | 350W x 630D x 560Hmm 40Kg approx. |

| Air | 0.3Mpa or more |

The specification are subject to change without notice.

The nozzles are made by request of the customer needs.

M.S.Engineering Co.,Ltd.

1-38-15, Okusawa, Setagaya-Ku, Tokyo, 158-0083 Japan. Phone: +81-3-4283-3951 Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

1-38-15, Okusawa, Setagaya-Ku, Tokyo, 158-0083 Japan. Phone: +81-3-4283-3951 Fax: +81-3-3728-5232

Copyright(C)2007 M.S.Engineering Co.,Ltd. All rights Reserved.

PDF for Printing

PDF for Printing